This is why you don't want to wreck your high-tech EVs!

31 Jan 2024|115,054 views

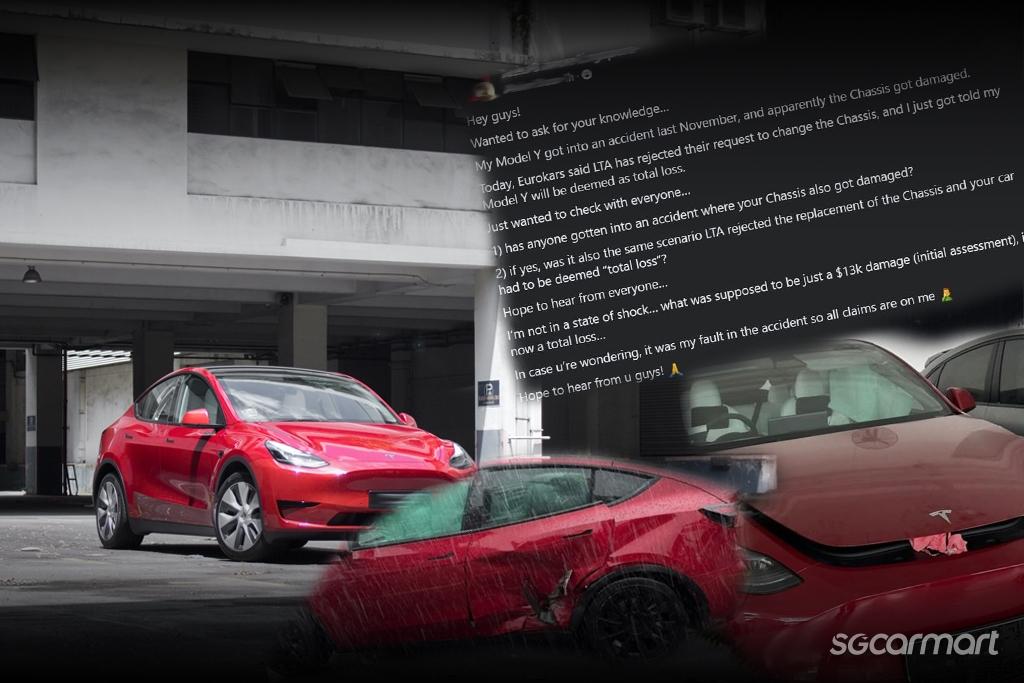

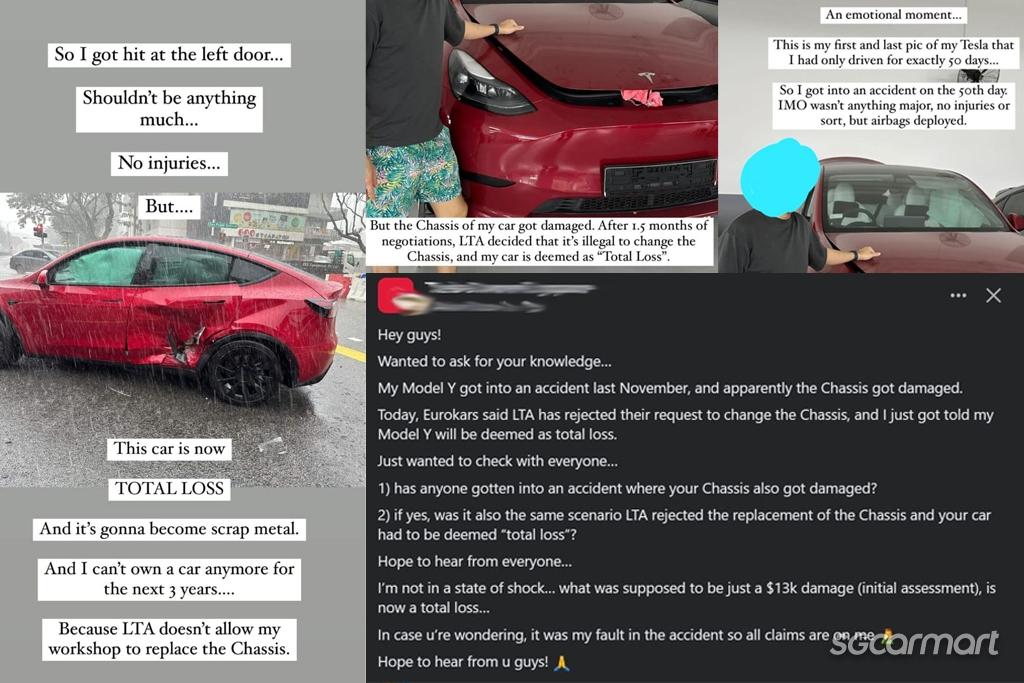

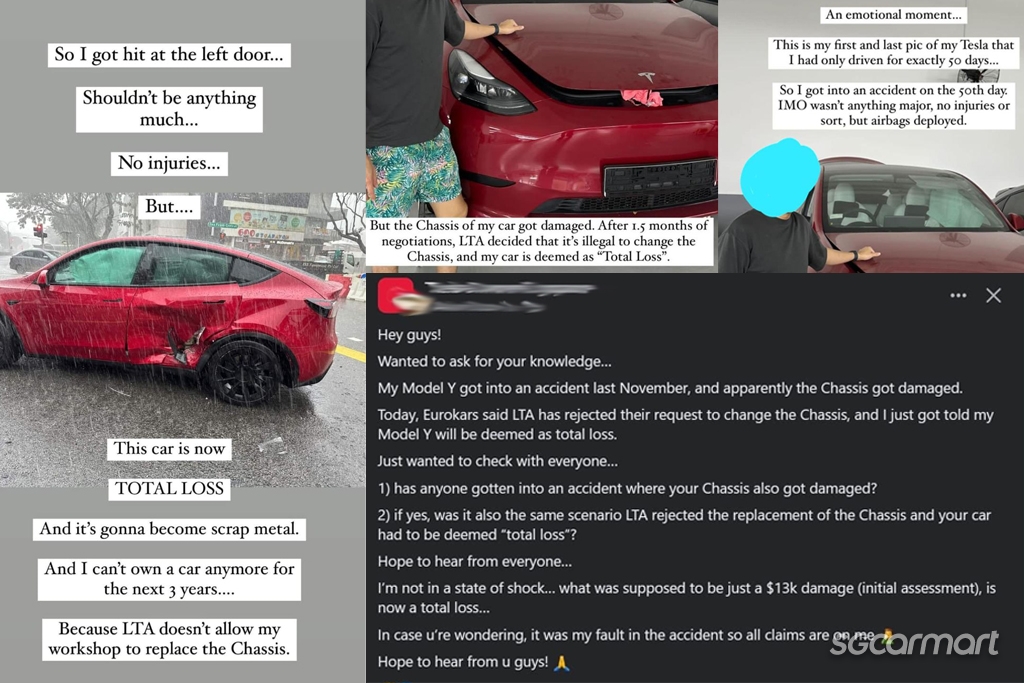

You might have read about a recent incident where a driver got into an accident in his Tesla Model Y and the car was deemed to be unrepairable - the service centre determined that a complete chassis replacement was necessary. However, the Land Transport Authority (LTA) forbids such a repair.

There are typically two types of reactions to the incident. On one side are people who found it normal - after all, it is not uncommon for badly damaged cars to be deemed unrepairable and 'totalled'. However, on the other hand, there are people who are shocked by the drastic repair procedure that will require a complete chassis replacement when the damage did not seem too nasty.

While the extent of the damage on a vehicle can't simply be determined from a photo of the exterior, hence we don't know just how badly damaged the car was, this incident got me thinking about the possible complications of repairing such a high-tech EV. Are these cars more difficult to repair than traditional ones? So I've decided to dig in to find out more.

Can a high-tech manufacturing process be a bad thing?

The car in question is one of Tesla's newest creations, the Model Y. It was built with cutting-edge technology, including one that made the news as a revolutionary step in the advancement of the car manufacturing process - Giga-casting.

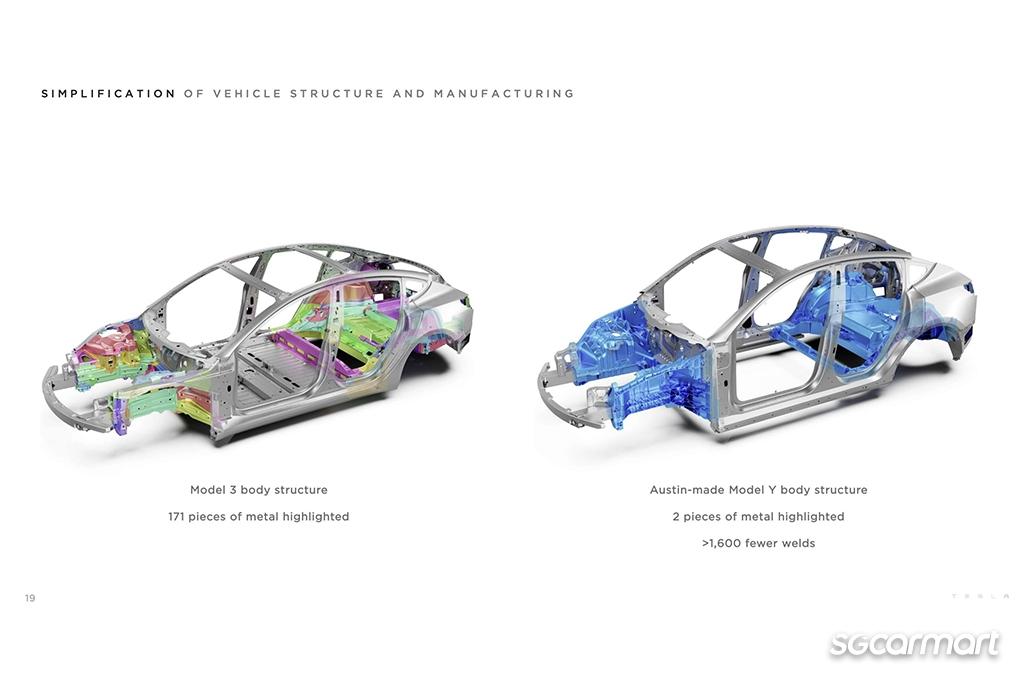

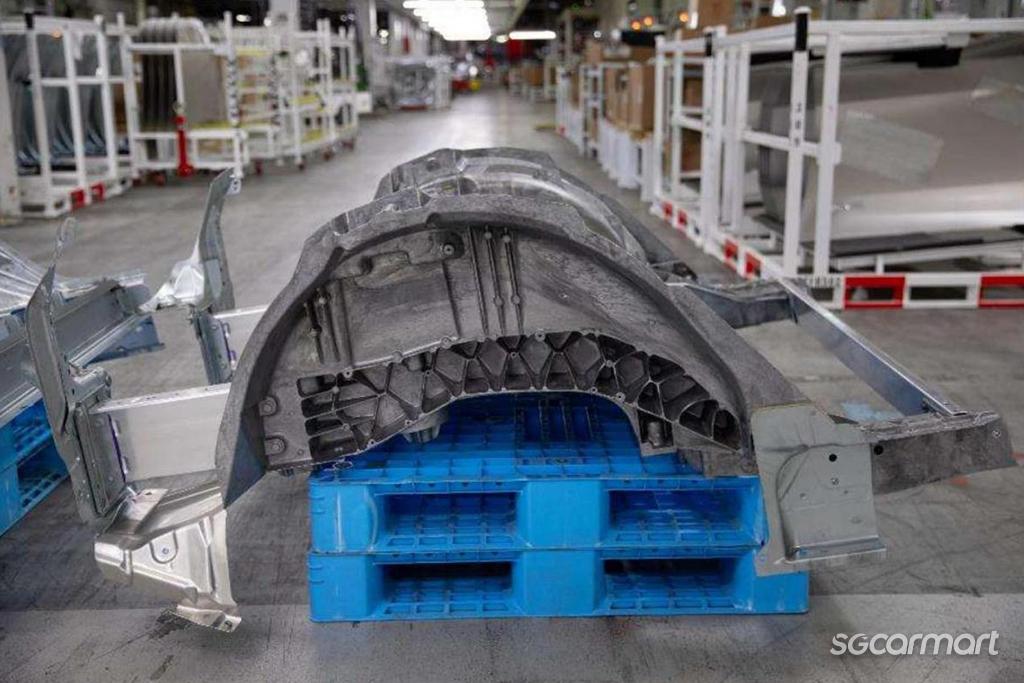

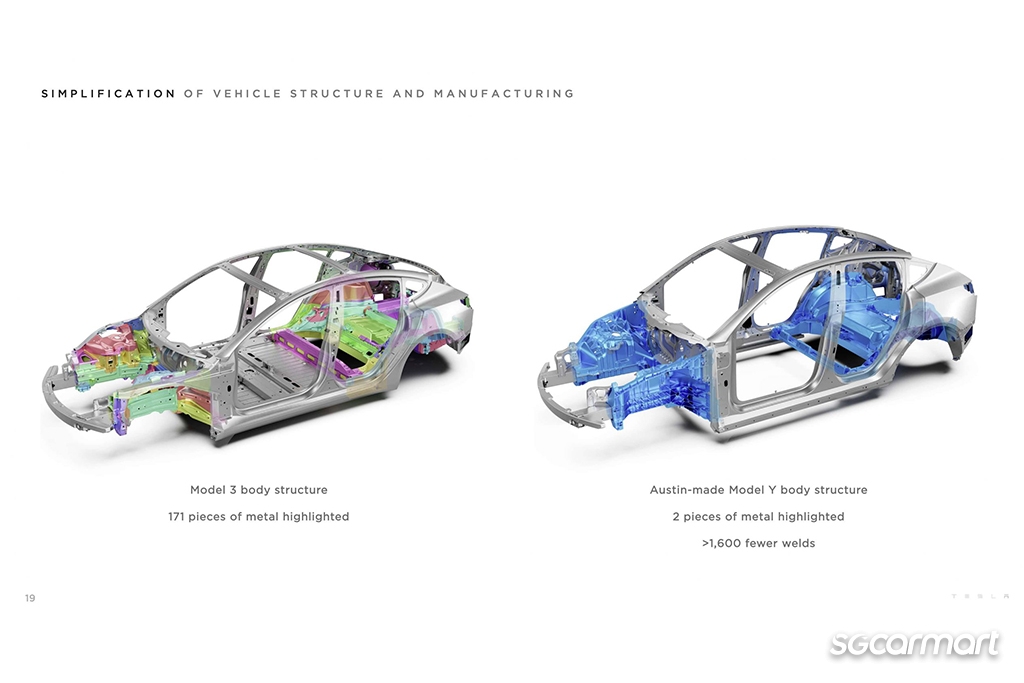

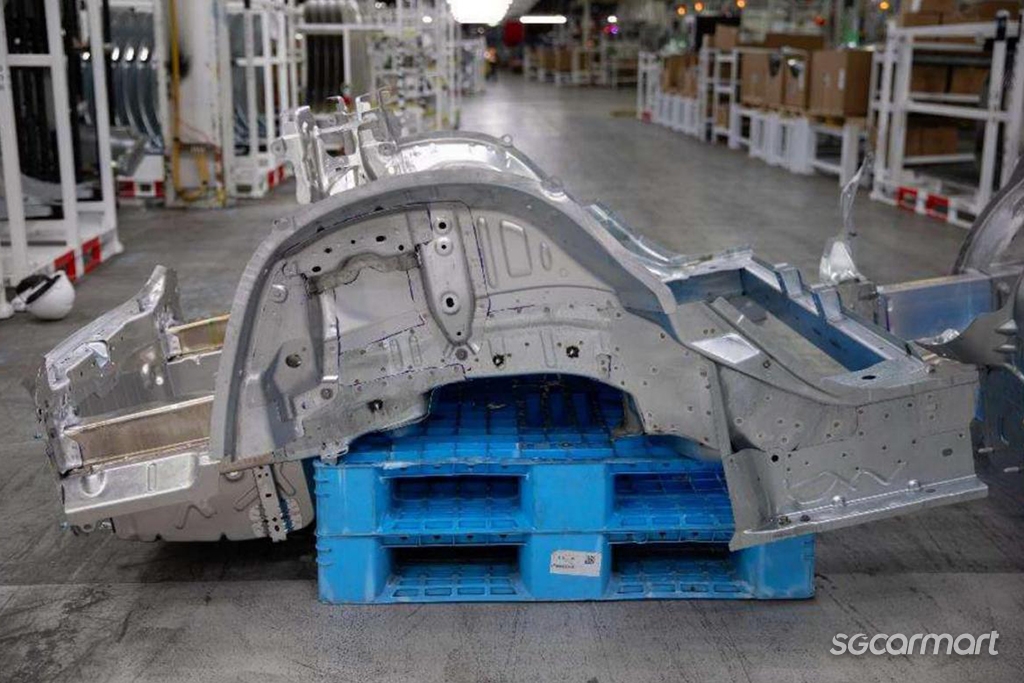

By using massive high-pressure aluminium die-casting machines, the brand is able to produce large aluminium pieces of the car's chassis in a quick, simple process. As opposed to the traditional way of welding together smaller stamped steel pieces to create parts of the chassis, Giga-casting saves time and money by simplifying the manufacturing process and keeping manpower costs low.

It is clear to see that the Giga-casted Model Y rear underbody is much simpler than the Model 3's that is stitched together with 70 pieces of metal - while simpler, it also means that damage to the structure will require it to be replaced in its entirety

While such processes mean that carmakers such as Tesla can build cars more quickly, and possibly sell them at a lower price by passing on the savings, it is not without its drawbacks.

Unlike the traditionally welded sections that can be individually replaced if required, allowing one to avoid replacing the entire chassis structure, a large single-piece structure means that the entire structure will have to be replaced when it has been damaged. Parallels can also be drawn to the carbon fibre monocoque found in supercars where damage to it could easily result in the entire car being written off due to the hefty costs to repair, or to replace the entire monocoque.

As a result, a minor accident on a car with large single-piece structures might result in a damage that requires a much more involved process to repair. It is likely to be costly, and in the case of the LTA, unlawful to be done as they do not allow a substantial part of a car's chassis to be replaced or substantially modified.

Aluminium is light and strong, and hence a material that is favoured by car manufacturers - the Alpine A110 is largely constructed of aluminium

Does the use of aluminium make repairs more difficult?

Aluminium has become the go-to material for modern cars, including EVs, as it is lighter than steel and yet, strong enough to craft vehicle components out of - the term aircraft-grade aluminium comes to mind.

However, the use of aluminium presents a new problem for repair works. Unlike steel, which is highly malleable and can be worked back into shape with relative ease after it has deformed, aluminium is much more difficult to work with.

Shaving weight off isn't just beneficial for performance, less weight equates to better economy - aluminium quickly found its way into many EVs, such as the Jaguar I-PACE

While aluminium isn't totally unrepairable, you can't just simply knock them back into shape like you would with deformed steel. Doing it haphazardly will result in cracking and other issues that will render the component unsafe and unusable.

On modern cars, aluminium is often used in body panels for weight saving reasons. Although these panels are typically easy to replace, it will inevitably cost more than repairing a damaged steel panel.

But the real problem occurs when the affected aluminium part is a major component that can't be easily replaced. In this particular case, the fact that the Giga-casted rear chassis of the Model Y is made of aluminium adds on to the complexity of the case - there's no easy way to repair the part without replacing it.

What part do batteries play when it comes to EV repairs?

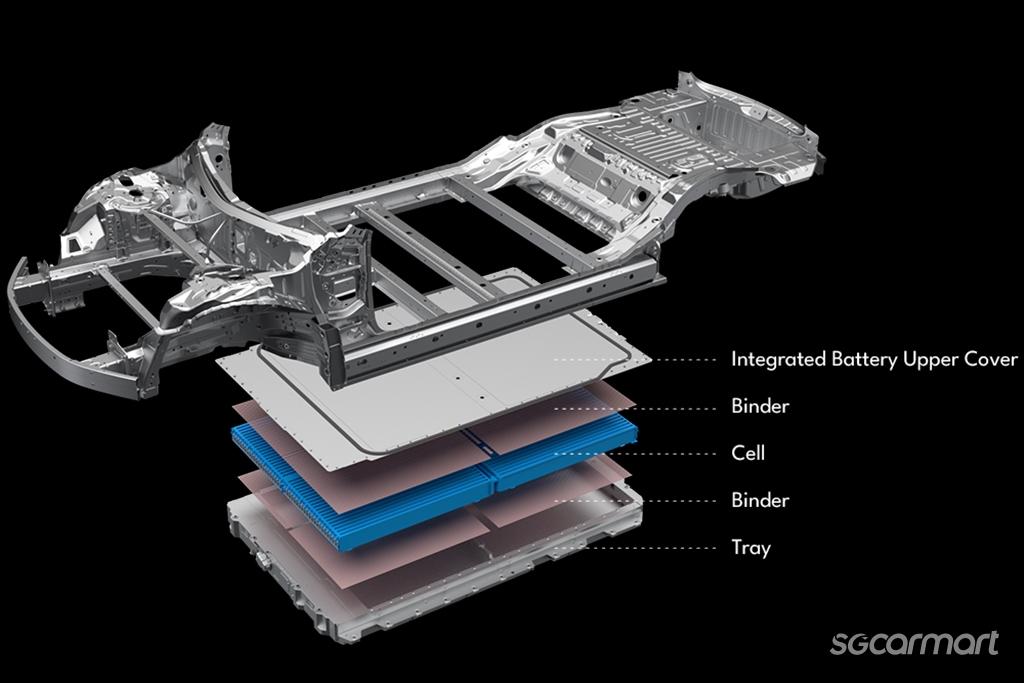

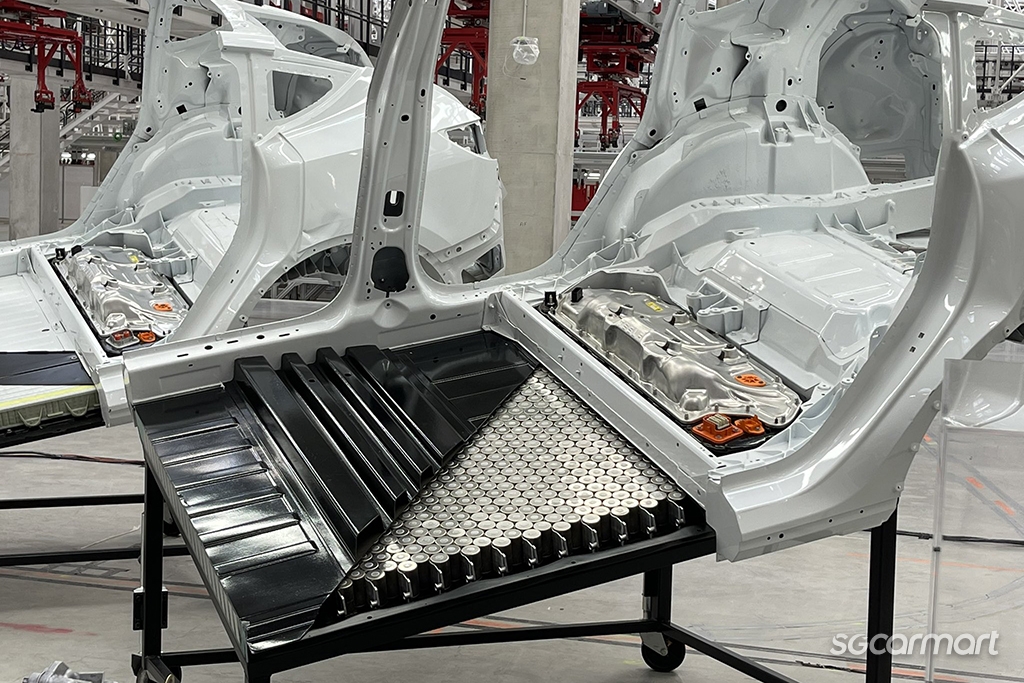

In many cases around the world, battery damage is yet another major concern and cost determinant when it comes to EV accident and repair works. EV batteries have always been a concern - people are worried that it could be a major fire hazard even though they have been proven to be safe and stable in such applications.

You can easily find articles mentioning the many EVs with lightly damaged battery housings that are decommissioned, or required by the manufacturer or insurance companies and the authorities to have the expensive battery replaced. As a result, any damage to the battery, no matter how superficial it seems, can likely result in hefty repair costs. And this is much more common that you think as after all, the batteries in EVs are typically packed in the floor of the car.

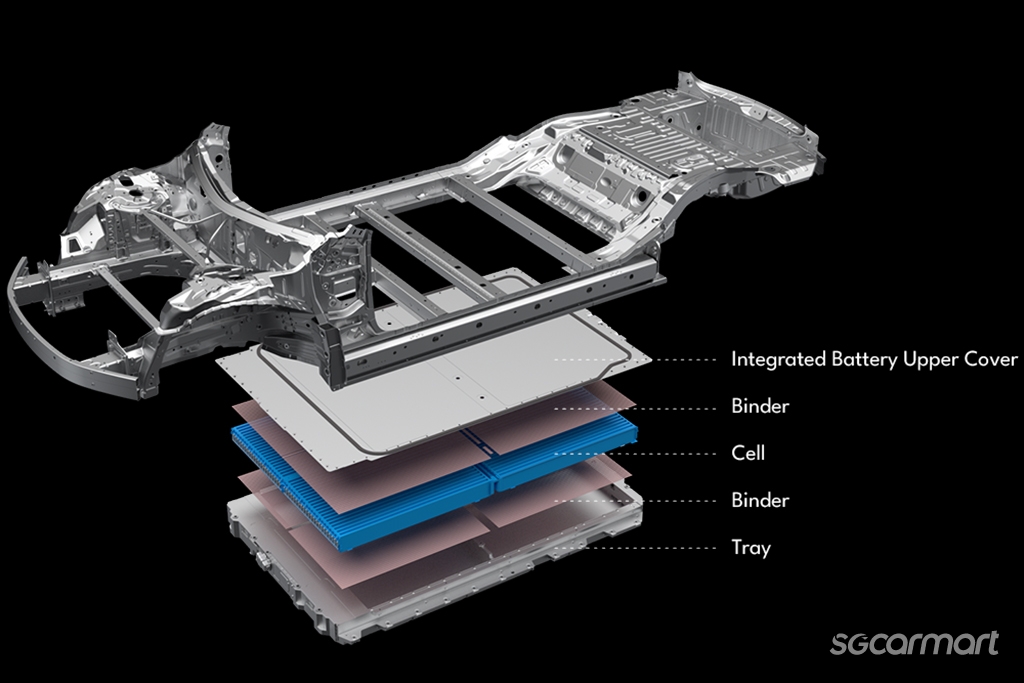

Meanwhile, there is another concern. The latest trend where manufacturers are making the car battery a structural component (by integrating the battery with the chassis) in order to save weight, improve performance and streamline manufacturing processes, could make a battery replacement procedure potentially more difficult and costly. The Tesla Model Y is an example of a recent EV that is built this way.

And you can imagine what happens when there's an impact that is sufficient to damage the chassis - with the battery built into the chassis structure, one would surely be concerned about the battery's condition.

What does this all mean for EV buyers?

Thanks to the advancement in materials and manufacturing processes, EVs are now cheaper than ever, and their performance are only going to keep getting better and more impressive.

However, as you can see from the adoption of Giga-casting, aluminium and structural batteries, these cars are becoming more difficult and expensive to repair in the event of an accident. Furthermore, even if one is willing to proceed with the costly repair, they could still run into trouble with the authorities. As the automotive industry forges ahead with new material and manufacturing processes, new car repair procedures could be established.

But, if the LTA and authorities from all over the world do not update their rulebooks to allow manufacturers and their authorised workshops to conduct these contemporary repair procedures, such as the replacement of an entire chassis to keep a car roadworthy, owners will be forced to write off their damaged cars unnecessarily.

This will only serve to put off potential adopters of EVs, result in more wastage, and the effect is ultimately counterintuitive to the world's efforts to promote sustainability and a greener motoring environment.

You might have read about a recent incident where a driver got into an accident in his Tesla Model Y and the car was deemed to be unrepairable - the service centre determined that a complete chassis replacement was necessary. However, the Land Transport Authority (LTA) forbids such a repair.

There are typically two types of reactions to the incident. On one side are people who found it normal - after all, it is not uncommon for badly damaged cars to be deemed unrepairable and 'totalled'. However, on the other hand, there are people who are shocked by the drastic repair procedure that will require a complete chassis replacement when the damage did not seem too nasty.

While the extent of the damage on a vehicle can't simply be determined from a photo of the exterior, hence we don't know just how badly damaged the car was, this incident got me thinking about the possible complications of repairing such a high-tech EV. Are these cars more difficult to repair than traditional ones? So I've decided to dig in to find out more.

Can a high-tech manufacturing process be a bad thing?

The car in question is one of Tesla's newest creations, the Model Y. It was built with cutting-edge technology, including one that made the news as a revolutionary step in the advancement of the car manufacturing process - Giga-casting.

By using massive high-pressure aluminium die-casting machines, the brand is able to produce large aluminium pieces of the car's chassis in a quick, simple process. As opposed to the traditional way of welding together smaller stamped steel pieces to create parts of the chassis, Giga-casting saves time and money by simplifying the manufacturing process and keeping manpower costs low.

It is clear to see that the Giga-casted Model Y rear underbody is much simpler than the Model 3's that is stitched together with 70 pieces of metal - while simpler, it also means that damage to the structure will require it to be replaced in its entirety

While such processes mean that carmakers such as Tesla can build cars more quickly, and possibly sell them at a lower price by passing on the savings, it is not without its drawbacks.

Unlike the traditionally welded sections that can be individually replaced if required, allowing one to avoid replacing the entire chassis structure, a large single-piece structure means that the entire structure will have to be replaced when it has been damaged. Parallels can also be drawn to the carbon fibre monocoque found in supercars where damage to it could easily result in the entire car being written off due to the hefty costs to repair, or to replace the entire monocoque.

As a result, a minor accident on a car with large single-piece structures might result in a damage that requires a much more involved process to repair. It is likely to be costly, and in the case of the LTA, unlawful to be done as they do not allow a substantial part of a car's chassis to be replaced or substantially modified.

Aluminium is light and strong, and hence a material that is favoured by car manufacturers - the Alpine A110 is largely constructed of aluminium

Does the use of aluminium make repairs more difficult?

Aluminium has become the go-to material for modern cars, including EVs, as it is lighter than steel and yet, strong enough to craft vehicle components out of - the term aircraft-grade aluminium comes to mind.

However, the use of aluminium presents a new problem for repair works. Unlike steel, which is highly malleable and can be worked back into shape with relative ease after it has deformed, aluminium is much more difficult to work with.

Shaving weight off isn't just beneficial for performance, less weight equates to better economy - aluminium quickly found its way into many EVs, such as the Jaguar I-PACE

While aluminium isn't totally unrepairable, you can't just simply knock them back into shape like you would with deformed steel. Doing it haphazardly will result in cracking and other issues that will render the component unsafe and unusable.

On modern cars, aluminium is often used in body panels for weight saving reasons. Although these panels are typically easy to replace, it will inevitably cost more than repairing a damaged steel panel.

But the real problem occurs when the affected aluminium part is a major component that can't be easily replaced. In this particular case, the fact that the Giga-casted rear chassis of the Model Y is made of aluminium adds on to the complexity of the case - there's no easy way to repair the part without replacing it.

What part do batteries play when it comes to EV repairs?

In many cases around the world, battery damage is yet another major concern and cost determinant when it comes to EV accident and repair works. EV batteries have always been a concern - people are worried that it could be a major fire hazard even though they have been proven to be safe and stable in such applications.

You can easily find articles mentioning the many EVs with lightly damaged battery housings that are decommissioned, or required by the manufacturer or insurance companies and the authorities to have the expensive battery replaced. As a result, any damage to the battery, no matter how superficial it seems, can likely result in hefty repair costs. And this is much more common that you think as after all, the batteries in EVs are typically packed in the floor of the car.

Meanwhile, there is another concern. The latest trend where manufacturers are making the car battery a structural component (by integrating the battery with the chassis) in order to save weight, improve performance and streamline manufacturing processes, could make a battery replacement procedure potentially more difficult and costly. The Tesla Model Y is an example of a recent EV that is built this way.

And you can imagine what happens when there's an impact that is sufficient to damage the chassis - with the battery built into the chassis structure, one would surely be concerned about the battery's condition.

What does this all mean for EV buyers?

Thanks to the advancement in materials and manufacturing processes, EVs are now cheaper than ever, and their performance are only going to keep getting better and more impressive.

However, as you can see from the adoption of Giga-casting, aluminium and structural batteries, these cars are becoming more difficult and expensive to repair in the event of an accident. Furthermore, even if one is willing to proceed with the costly repair, they could still run into trouble with the authorities. As the automotive industry forges ahead with new material and manufacturing processes, new car repair procedures could be established.

But, if the LTA and authorities from all over the world do not update their rulebooks to allow manufacturers and their authorised workshops to conduct these contemporary repair procedures, such as the replacement of an entire chassis to keep a car roadworthy, owners will be forced to write off their damaged cars unnecessarily.

This will only serve to put off potential adopters of EVs, result in more wastage, and the effect is ultimately counterintuitive to the world's efforts to promote sustainability and a greener motoring environment.

Thank You For Your Subscription.